commensurate

12 Oct 2025

Challenge details:

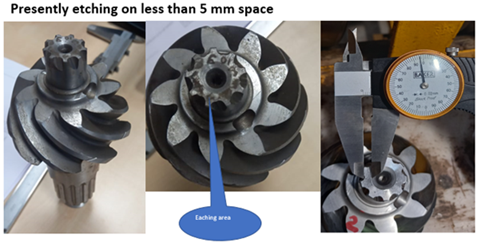

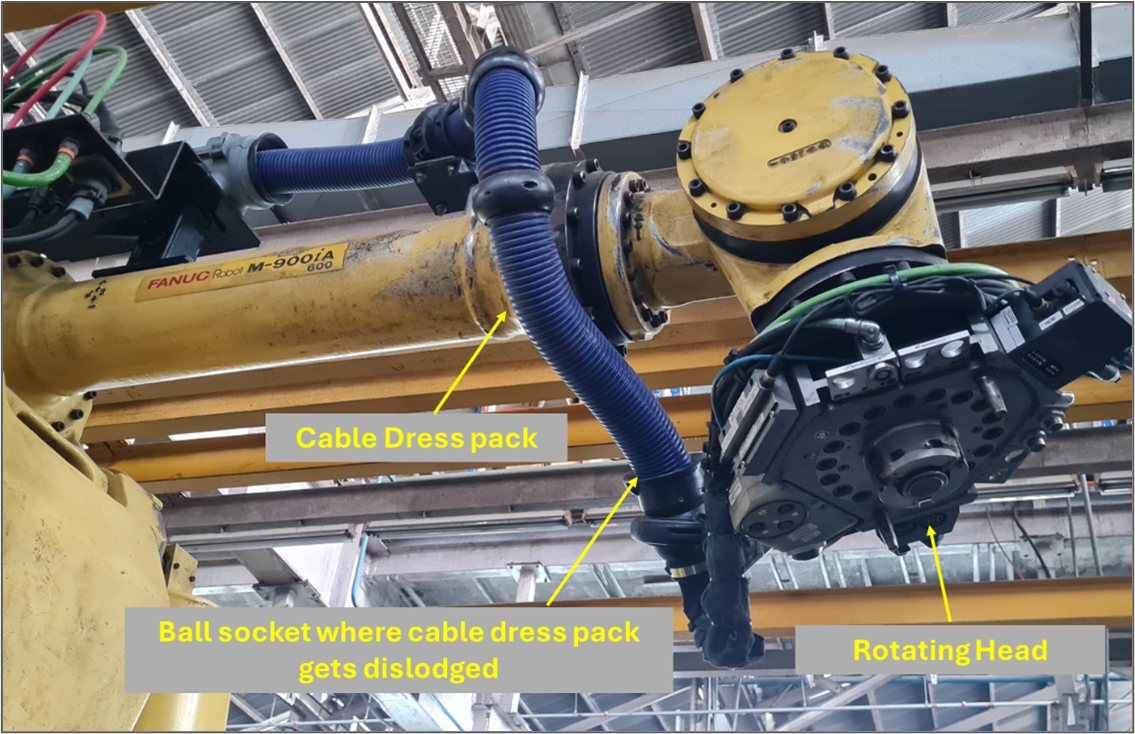

Copper slag blasting is a process that uses copper slag as an abrasive material to clean and prepare surfaces, particularly metal, for further treatment like painting or coating. It involves propelling copper slag particles at high velocity using compressed air to remove contaminants like rust, scale, and old paint. The difficulty arises when the blasting needs to be carried out in areas where final products like soda ash, bicarb & vacuum salt (both food grade) are being handled as the blasting may cause contamination by the dust which is inherent to the blasting process. In addition, blasting cannot be carried out in areas where critical high speed rotating machines like turbines & pumps with motors exist as impingement of abrasives with bearings/seals, electrical components may cause damage to the equipment.

To avoid the above problems, the equipment in the blasting areas are covered with tarpaulins/masking as shown in the images. However, it is not always possible to shield the equipment completely and slag blasting needs to be put-off at areas while in operation. We are thus, actively seeking for solutions that can eliminate the need for slag blasting altogether, especially in sensitive zones, while still achieving effective surface cleaning.