commensurate

10 Nov 2025

| 16 Day(s) LeftChallenge details:

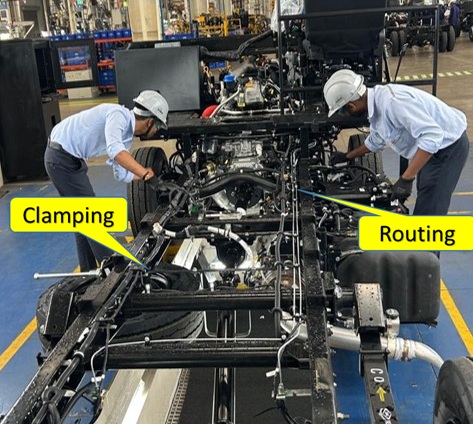

At the End-of-Line (EOL) and Pre-Delivery Inspection (PDI) stages of chassis assembly, ensuring correct clamping and routing of components is critical for vehicle safety and reliability. However, the complexity of the chassis assembly process—particularly involving brake lines, fuel lines, electrical harnesses, and coolant hoses—makes it prone to errors. These components need to be assembled in constrained spaces, with their routing paths overlapping, leading to entanglement, stress points, or incorrect layering that may not be immediately visible.

In addition, these components (clamps, brackets, connectors etc.) are similar in dimensions and appearance, which may result in incorrect part fitment. Missing components or misrouted cables can compromise functionality and are often hard to detect without detailed inspection.

Currently, the detection of such issues relies heavily on manual inspection, which involves checking 30-40 parameters per vehicle. This process is vulnerable to human error, particularly under time constraints or when performed by less experienced personnel. The problem is compounded as the workforce is floating and may lack familiarity with specific chassis configuration.

We are seeking solutions which can accurately and efficiently detect these defects during the End-of-Line/Pre-Delivery Inspection stage.